Digital workplace design

The aim of ergonomic workplace design or ergonomic product development is to adapt spatial arrangements and time sequences to the anatomical and physiological needs of people.

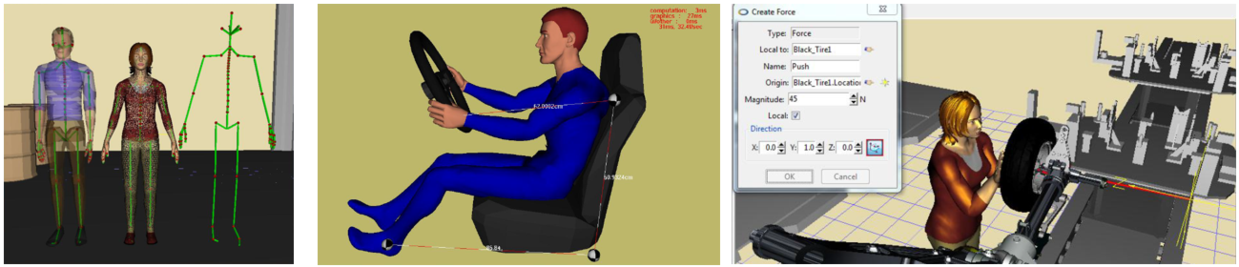

For this purpose, digital human models are created on the basis of anthropometric data. In addition, an environmental geometry is created in which the model is imported. Postures, movement sequences and field of vision conditions can then be determined. In the simulation, dimensions, forces and visual conditions can be interactively checked and optimized.

Digital human models, such as the Anybody Modeling System™, Siemens Jack or ema's human model, depict musculoskeletal structures and make it possible to calculate body forces and torques. In this way, mechanical body loads can be determined and assessed.

ema Software Suite

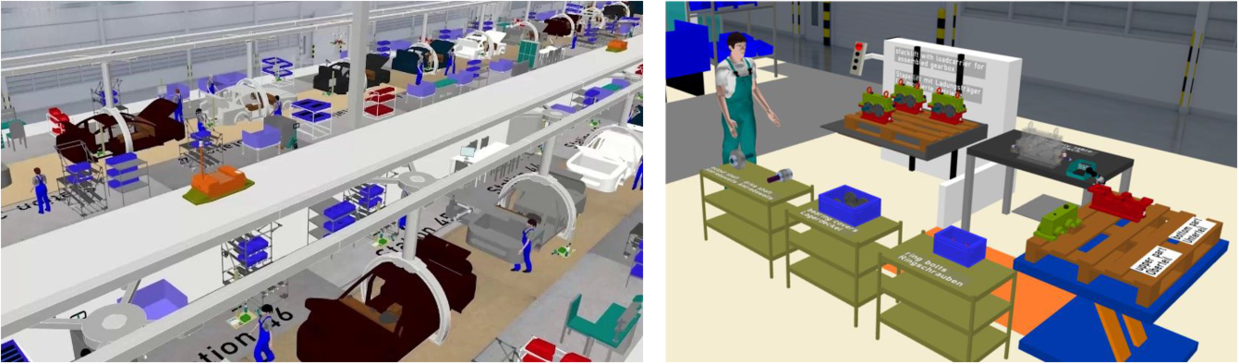

The ema Software Suite is a simulation solution for planning sustainable factories and ergonomic as well as efficient workplaces. The software consists of two modules: ema Plant Designer and ema Work Designer.

The ema Plant Designer enables the precise planning and evaluation of entire production processes. With ema Work Designer, workstations can be designed in detail, manual activities and human-robot interactions can be visualized and complete manufacturing and assembly processes can be simulated in 3D. Based on the simulations with digital human models, automated time management and ergonomic analyses can be carried out, for example, in order to derive targeted optimization measures for the workplace.

Siemens Tecnomatix Jack

Siemens Tecnomatix Jack is a powerful software for digital human modeling and ergonomics analysis. It enables the simulation of human movements in virtual environments in order to optimize workplaces, production processes and products with regard to ergonomic requirements. Jack is used in industry and research to analyze stress on the human body, minimize the risk of musculoskeletal disorders and improve the usability of designs. Thanks to integrated biomechanical models, the software supports well-founded decisions in the fields of ergonomics, vehicle development and medical technology.

AnyBody Technology

The AnyBody Technology software enables the simulation and analysis of the human musculoskeletal system on the basis of biomechanical models. It is used in research and industry to investigate loads on joints, muscles and bones. By using motion capture data or individual movement analyses, precise muscle forces and loads can be calculated.